Historical Context of Antique Brass Cabinet Hardware

Antique brass cabinet hardware, far from being merely functional, offers a captivating glimpse into the evolution of design, manufacturing, and societal tastes. Its journey, from rudimentary fastenings to exquisitely crafted embellishments, mirrors broader technological and aesthetic shifts throughout history. The enduring appeal of antique brass lies not only in its inherent beauty but also in its ability to connect us to the past, whispering stories of craftsmanship and bygone eras.

Antique brass cabinet hardware – The earliest forms of brass hardware were largely utilitarian, focusing on functionality over aesthetics. Simple latches, hinges, and handles, often forged from wrought brass, served their purpose without much ornamentation. As metalworking techniques improved, particularly with the advent of more sophisticated casting methods, decorative elements began to appear. The rise of mass production in the 19th and 20th centuries further democratized access to brass hardware, leading to a wider variety of styles and increased affordability.

Manufacturing Processes of Brass Cabinet Hardware Through History

Early brass hardware was predominantly crafted through forging, a labor-intensive process involving shaping the metal through hammering and heating. This method resulted in unique variations and textures, reflecting the hand of the artisan. Later, the development of sand casting allowed for more intricate designs and mass production. Lost-wax casting, a more precise technique, emerged later, enabling the creation of even more detailed and complex pieces. The 20th century saw the rise of die casting, a highly efficient process that further reduced costs and increased production volume. Each of these methods left its mark on the final product, influencing the overall appearance and feel of the hardware. For instance, forged pieces often exhibit a more rustic charm, while die-cast items may appear smoother and more uniform.

Styles of Antique Brass Cabinet Hardware Across Historical Periods

The styles of antique brass cabinet hardware reflect the prevailing aesthetic trends of each era. A comparison across several significant periods reveals fascinating contrasts and continuities.

| Period | Style Characteristics | Common Materials | Notable Examples |

|---|---|---|---|

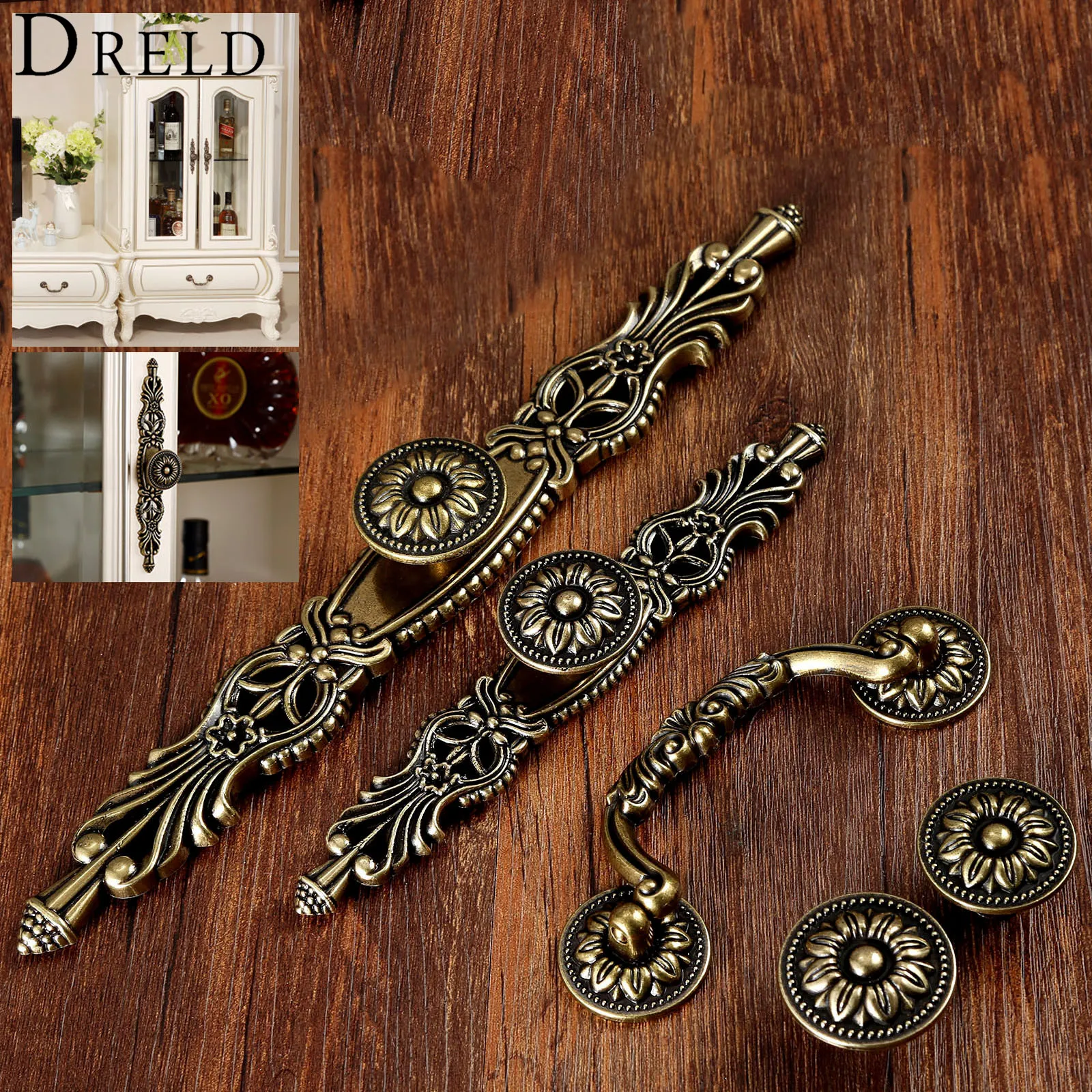

| Victorian (1837-1901) | Ornate, elaborate designs; often featuring floral motifs, scrolling patterns, and heavy use of castings; dark, rich brass tones. | Brass, sometimes combined with other metals like iron or steel. | Large, decorative door knobs; intricately carved drawer pulls; ornate hinges with decorative finials. |

| Edwardian (1901-1910) | Similar to Victorian, but with a slightly more streamlined and less cluttered aesthetic; emphasis on quality craftsmanship and fine detailing; often incorporated Art Nouveau influences. | High-quality brass, sometimes with silver or enamel accents. | Subtle floral motifs; more geometric patterns than the Victorian era; refined drawer pulls and knobs. |

| Art Deco (1920s-1930s) | Geometric shapes; clean lines; symmetrical designs; often incorporating stylized motifs like sunbursts, zigzags, and chevrons; polished brass finish. | Highly polished brass; sometimes combined with chrome or other modern materials. | Sleek, minimalist handles; geometric drawer pulls; simple but elegant hinges. |

| Mid-Century Modern (1940s-1960s) | Simple, functional designs; clean lines; emphasis on practicality and minimalism; often featuring brushed or satin brass finishes. | Brass, often combined with wood or other natural materials. | Simple, unadorned knobs; minimalist pulls; flush-mounted hinges. |

Identifying and Appraising Antique Brass Cabinet Hardware

The allure of antique brass cabinet hardware lies not only in its aesthetic charm but also in its potential value. Understanding how to identify, date, and appraise these pieces unlocks a deeper appreciation for their history and craftsmanship, transforming a simple decorative element into a potential investment or treasured heirloom. This guide provides a framework for discerning collectors and enthusiasts seeking to navigate the world of antique brass hardware.

Maker’s Marks and Hallmarks

Identifying maker’s marks and hallmarks is crucial for authentication and provenance. These markings, often subtly etched or stamped on the hardware, can reveal the manufacturer, period of production, and even the specific workshop where the piece was created. Common locations for these marks include the underside of knobs, the back plates of handles, or within intricate design elements. While some manufacturers used elaborate logos or monograms, others employed simpler codes or initials. Researching antique hardware catalogs and manufacturer directories from relevant periods is invaluable in deciphering these marks. For example, a distinctive “A&S” hallmark might indicate a piece from a specific Birmingham-based workshop, while a stylized floral motif could point to a particular French manufacturer active during the Art Nouveau period. Careful examination with magnification, coupled with thorough research, is key to uncovering these often-hidden clues.

Determining Age and Origin Through Design and Construction

The design features and construction techniques employed in antique brass cabinet hardware offer strong indicators of its age and origin. Styles evolved over time, reflecting prevailing aesthetic trends and technological advancements. For example, the ornate, hand-carved details of 18th-century hardware contrast sharply with the simpler, more geometric designs of early 20th-century pieces. Similarly, casting techniques and the use of specific alloys changed throughout history. Early pieces might show evidence of hand-finishing and imperfections indicative of artisanal production, whereas later pieces often exhibit a more uniform, machine-produced appearance. The presence of specific materials, such as particular types of brass alloys or the use of inlay techniques, can also help narrow down the timeframe and geographical origin. Comparing the hardware to known examples from documented collections or museum archives is a valuable method for cross-referencing and confirming estimations.

Factors Influencing Value

The value of antique brass cabinet hardware is determined by a complex interplay of several key factors. Understanding these elements allows for a more accurate assessment of a piece’s worth.

- Rarity: The scarcity of a particular design, maker’s mark, or production period significantly impacts its value. Unique or limited-edition pieces command higher prices.

- Condition: The overall condition of the hardware is paramount. Intactness, the presence of original finishes, and the absence of significant damage or repairs all contribute to its desirability and value. Minor wear is often acceptable and even adds to the charm, but extensive damage diminishes value considerably.

- Provenance: A documented history of ownership adds significant value, especially if the piece can be linked to a notable individual or historical event. Provenance adds authenticity and enhances the narrative surrounding the object.

These factors are not equally weighted; rarity and condition typically hold the most influence, while provenance can substantially increase value in exceptional cases. For instance, a rare set of Victorian-era door handles in pristine condition, with documented ownership tracing back to a renowned architect, would command a significantly higher price than a common, mass-produced piece in fair condition with an unknown history.

Visual Guide to Common Signs of Wear and Tear

A visual assessment of wear and tear is critical for determining condition and, consequently, value.

- Patina: A natural, even patina, indicative of age and gentle use, often enhances a piece’s value. However, uneven or excessive discoloration, suggesting neglect or improper cleaning, detracts from its appeal.

- Scratches and Dents: Minor scratches and dents are common and may be considered acceptable signs of age, particularly on pieces with significant age. However, deep gouges, significant pitting, or structural damage will substantially reduce value.

- Corrosion: Significant corrosion, often manifested as pitting or green verdigris, indicates deterioration and significantly reduces value. This is often irreversible and compromises the integrity of the piece.

- Missing or Damaged Parts: Missing knobs, broken handles, or damaged backplates dramatically reduce value. Incomplete sets are less desirable and command lower prices than complete, undamaged sets.

- Repairs: While some repairs might be acceptable, poorly executed repairs or the use of inappropriate materials will detract from value. The presence of obvious repairs should be disclosed transparently.

Restoring and Maintaining Antique Brass Cabinet Hardware

The allure of antique brass cabinet hardware lies not only in its historical significance but also in its enduring beauty. However, the passage of time inevitably leaves its mark, requiring careful restoration and ongoing maintenance to preserve these exquisite pieces. Understanding the delicate nature of antique brass is crucial to ensure that any cleaning, repair, or polishing techniques used will enhance, not diminish, their value and aesthetic appeal.

Gentle Cleaning Methods for Antique Brass Hardware

Cleaning antique brass requires a delicate touch. Harsh chemicals and abrasive materials can easily scratch or damage the delicate patina, reducing the piece’s value and altering its character. Instead, opt for gentle methods that remove dirt and grime without harming the underlying metal. A soft, lint-free cloth dampened with lukewarm water is often sufficient for routine cleaning. For more stubborn grime, a mild soap solution—a few drops of dish soap in warm water—can be used, ensuring the hardware is thoroughly rinsed and dried immediately afterward. Never submerge antique brass in water, as this can lead to corrosion.

Repairing Minor Damage to Antique Brass

Minor scratches and dents can be addressed with careful techniques. For superficial scratches, a very fine-grit polishing compound applied with a soft cloth can often gently remove the imperfection. For deeper scratches or dents, a professional restoration specialist should be consulted. Attempting to repair significant damage without proper expertise may result in further damage. Remember, even minor repairs should be approached cautiously, with the goal of preserving the original patina as much as possible. A light touch is always preferable to aggressive action.

Polishing and Protecting Antique Brass Hardware

Polishing antique brass enhances its luster and protects it from further deterioration. However, excessive polishing can remove the desirable patina, which adds to the historical character and value of the piece. Therefore, polishing should be done sparingly and with a high-quality, non-abrasive brass polish. After polishing, a protective sealant, such as a clear wax or lacquer specifically designed for brass, can be applied to help maintain the shine and resist tarnishing. It’s crucial to follow the manufacturer’s instructions carefully for both the polish and the sealant to avoid damage.

A Typical Restoration Process

The restoration process often follows these steps:

- Assessment: Carefully examine the hardware to identify the extent of damage and determine the appropriate cleaning and restoration techniques.

- Gentle Cleaning: Use a soft cloth and lukewarm water, or a mild soap solution if necessary, to remove surface dirt and grime.

- Minor Repair: Address minor scratches with a fine-grit polishing compound. Consult a professional for more significant damage.

- Polishing: Apply a high-quality brass polish sparingly, following the manufacturer’s instructions.

- Protection: Apply a clear wax or lacquer designed for brass to protect the polished surface and prevent tarnishing.

- Drying: Allow the hardware to dry completely before reinstallation.